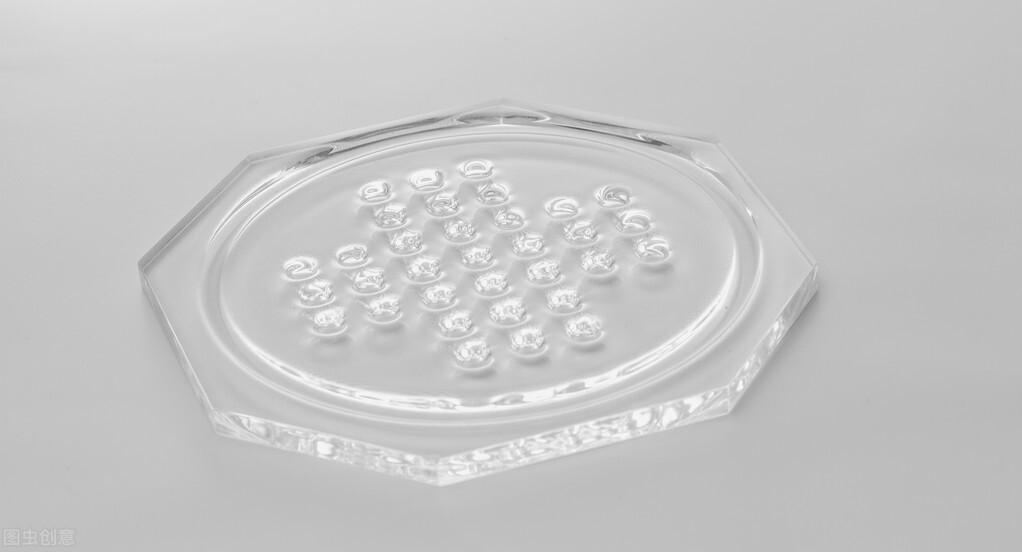

I-Acrylic, eyaziwa ngokuba yi-PMMA, yinto ebalulekileyo yeplastiki yepolymer imathiriyeli eyenziwe ngaphambili.Inokubonakala kakuhle, ukuzinza kweekhemikhali, ukudaya lula, ukusetyenzwa lula, kunye nenkangeleko entle.Inoluhlu olubanzi lwezicelo kuzo zonke iinkalo zobomi.

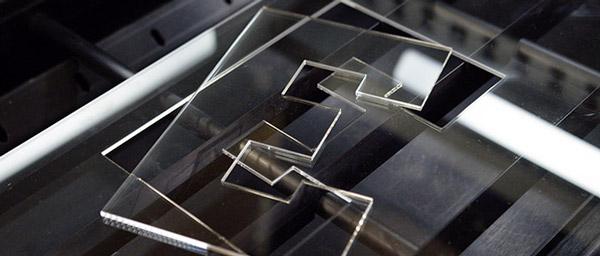

Iindlela zokusika i-Acrylic ziquka ukusika i-laser, ukusika imela ngesandla kunye nokusika imela engcangcazelayo.

Ukusika imela ngesandla ikakhulu kukusika ngesandla ngencakuba okanye i-chainsaw.Ukusika ngesandla iibhodi ze-acrylic kufuna ukucwangcisa ibhodi kwangaphambili, uze uyinqumle ngommese we-hook okanye i-chainsaw ngokwepatheni.Ukuba ufuna i-eddge ecocekileyo, ungayipolisha.Iimpawu kukuba ukusika kunzima, ukuchaneka kukubi, kwaye ukhuseleko lokusetyenziswa luphantsi.Ukuba usebenzisa i-chainsaw ukusika, iya kubangela ukuba i-acrylic inyibilike, eya kuba nefuthe elithile kubuhle bomkhiqizo osikiweyo.

Bobabini umatshini wokusika ummese wokungcangcazela kunye nomatshini wokusika we-laser usebenzisa ukusika umatshini.Inkqubo yokusika i-acrylic yile:

1. I-software yokuseta ngokuzenzekela

2. Beka izinto kwindawo yokusebenza

3. Umatshini uqala ukusika

Umatshini we-laser yindlela yokusika i-thermal, eya kuvelisa umsi omningi kunye nephunga elingathandekiyo ngexesha lokusika, kwaye ingxaki yokukhusela indalo inzima.Ngaphezu koko, ukusika ukushisa okuphezulu kuya kuvelisa i-phenomenon of edge edge kunye ne-black edge, echaphazela ngokukodwa umphumo wokusika kwaye ichaphazela umgangatho wemveliso.

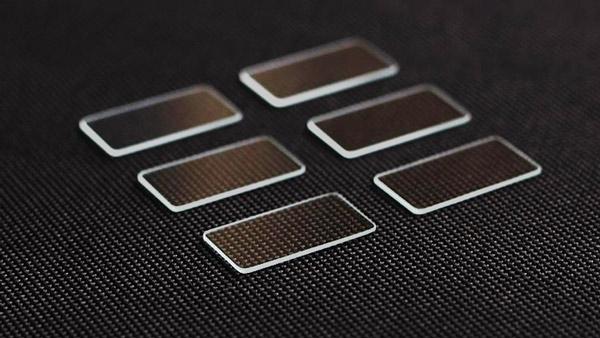

Ukusika ummese ongcangcazelayo kuneempawu zokukhuselwa kwendalo kwaye akukho msi kunye nothuli, kwaye unokutshintshwa ngeentloko ezahlukeneyo zokusika, iimela ezijikelezileyo, iimela zokubetha, ii-oblique iimela, njl. ukuseta uhlobo, olunokuphucula izinga lokusetyenziswa kwemathiriyeli ngaphezu kwe-90%.Ayigcini nje kuphela izinto eziphathekayo, kodwa igcina abasebenzi kwaye iphucula ukhuseleko lokusebenza.

Ixesha lokuposa: Sep-20-2022